Home > Robot Packing > Tray Packaging

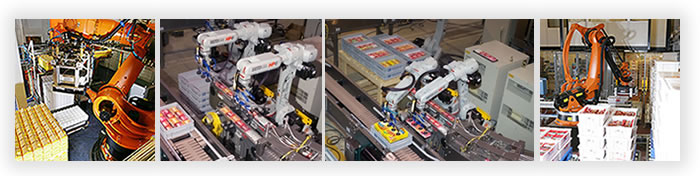

Robot Packing Equipment: Tray Packaging

Robot Palletizer, LLC designs and manufactures horizontal or vertical loading systems designed to load a variety of packaged products directly into containers including trays. Robot Palletizer offers tray loading solutions that are compact, flexible and reliable. Our packers provide multiple secondary functions, including case inspection, product inspection, sorting and distribution, cutting and case coding.

Robot Palletizer, LLC's packaging systems utilize high-speed robots that are compact and require minimal installation space. Our systems use an advanced NX100 controller that features a Window CE programming pendant, fast processing, and an easy-to-use INFORM III programming language.

the Finest Tray Packing Equipment

Features

- Widest working envelope in its class

- Industry leading + 0.06 mm (+ 0.002") repeatability

- Floor, wall, shelf, and ceiling-mounting options

- Advanced Sigma motors provide powerful, slim design

- Multiple robot control (up to four robots) simplifies programming and eliminates interference

- Various gripper mechanisms for variety of handling applications

- Small footprint reduces floor space

- Web server that allows remote monitoring and diagnosis (optional)

- MotoMax III three year warranty

Case Study KR 180 PA : How Gilde Benefited from our Tray Packaging Equipment

In the order-picking warehouse at Gilde in Tonsberg (Norway), the overriding concern is how to get freshly processed and packaged meat to the customer. About 140 employees currently sort customer orders. For some time now they have had a new colleague: a KUKA KR 180 PA robot. The robot takes care of the “fast movers”. This is the name given to the goods that are ordered most often, and which are consequently dispatched in large numbers.

The seasonally fluctuating “fast mover” products are produced in far higher numbers than the standard products. At Gilde they run on five production lines. In order to get them to the customer as fast as possible, an order-picking system able to handle the product diversity and also the increased capacity was required.

The KR 180 PA was chosen above all due to its long reach. Even though the roller conveyor leading into the cell is installed about three meters above floor level, the palletizing experts are able to take packages from it and to set them down near the floor. It was thus possible to avoid additional investment costs for the roller conveyor – thanks to the KR 180 PAs’ long reach, the conveyor did not have to be routed downwards.

Advantages of using Automated Tray Packing Systems

1. Reduced Labor Costs

2. Improved Product Quality

3. Elimination of Dangerous Jobs

4. Increase output rate

5. Increase product flexibility

6. Reduced Material Waste

7. Compliance with OSHA Regulations

8. Reduced Labor Turnover

9. Reduced Capital Costs